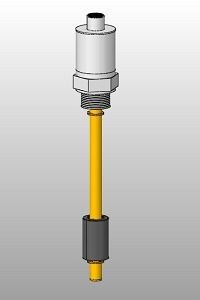

Analogue Level and Temperature Measurement Reed Chain

In today’s high-tech industrial environment, accurate level and temperature measurement in tanks, containers, and process systems is more critical than ever. These measurements are fundamental to efficient and safe operations. Analog level measurement using a reed chain, combined with temperature sensors such as PT100/PT1000 or a bimetallic temperature switch, has proven to be a reliable and effective solution. This technology enables continuous and precise monitoring of liquid levels while simultaneously measuring or controlling temperature.

Operating Principle:

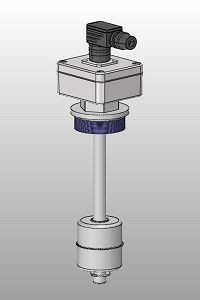

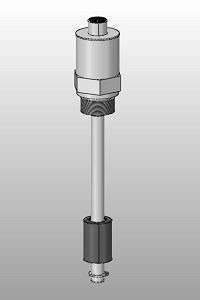

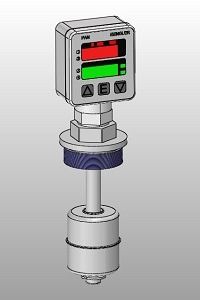

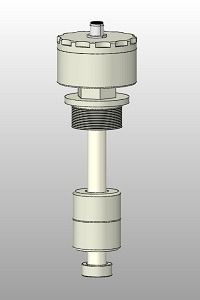

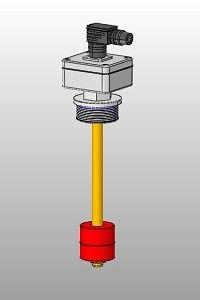

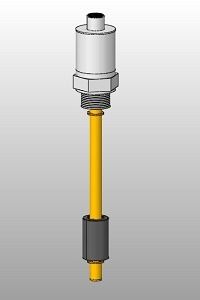

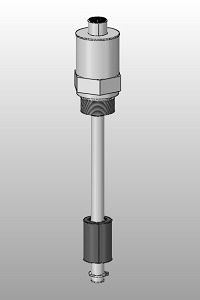

The operating principle of an analogue level sensor with a reed chain and float is based on the float's vertical movement with the liquid level. The sensor consists of a reed chain and a magnet-equipped float. The reed chain is made up of multiple reed switches mounted at regular intervals along a flexible metal strip, positioned vertically inside the container. Each reed switch contains two ferromagnetic contacts enclosed in a glass capsule.

As the liquid level rises or falls, the float moves accordingly, bringing its internal magnet close to successive reed switches. When the magnet nears a switch, the magnetic field causes the contacts to close, generating an electrical signal. These signals are captured by an evaluation unit and translated into a corresponding level measurement.

Analogue temperature measurementhighly accurate temperature sensors such as the PT100 or PT1000. These sensors operate on the principle that a metal’s electrical resistance changes with temperature. A PT100 sensor contains a platinum resistor that increases its resistance as temperature rises. The PT1000 functions similarly but has a nominal resistance of 1000 ohms at 0 °C, compared to 100 ohms for the PT100.

PT sensors provide precise and reliable resistance values that are directly correlated to the temperature of the medium they are in contact with. These analogue resistance values are then converted into temperature readings by a suitable measuring device or evaluation circuit. The resulting temperature data can be transmitted to control and automation systems for continuous monitoring, process control, or safety regulation.

A bimetallic switch consists of two metal strips with different coefficients of thermal expansion bonded together. When exposed to heat, the metals expand at different rates, causing the strip to bend. This mechanical deformation results in the movement of the switch mechanism.

The temperature switch uses the bimetallic strip as a sensing element to monitor temperature. When the temperature reaches or exceeds a pre-set threshold, the bending of the strip causes an electrical contact to either open or close.

If the contact opens, the circuit is interrupted and current flow stops—this can act as a safety feature, for example, to prevent overheating. When the contact closes, the circuit is completed and current can flow, enabling a control or activation function.

Advantages:

- Precise liquid and process monitoring

- Improved process efficiency and control

- Enhanced safety through early detection

- Reduced downtime with proactive maintenance

- Optimized use of resources and energy

- Consistent product quality

- Versatile for various applications

- Easy integration with control systems

- Long-term cost savings

- Lower environmental impact

Applications & Industries:

- Chemical/Petrochemical: Safe substance monitoring

- Food & Beverage: Ensures product quality

- HVAC Systems: Controls heating/cooling

- Environmental: Monitors waste tanks

- Pharmaceutical: Optimizes production

- Power Generation: Boosts energy efficiency

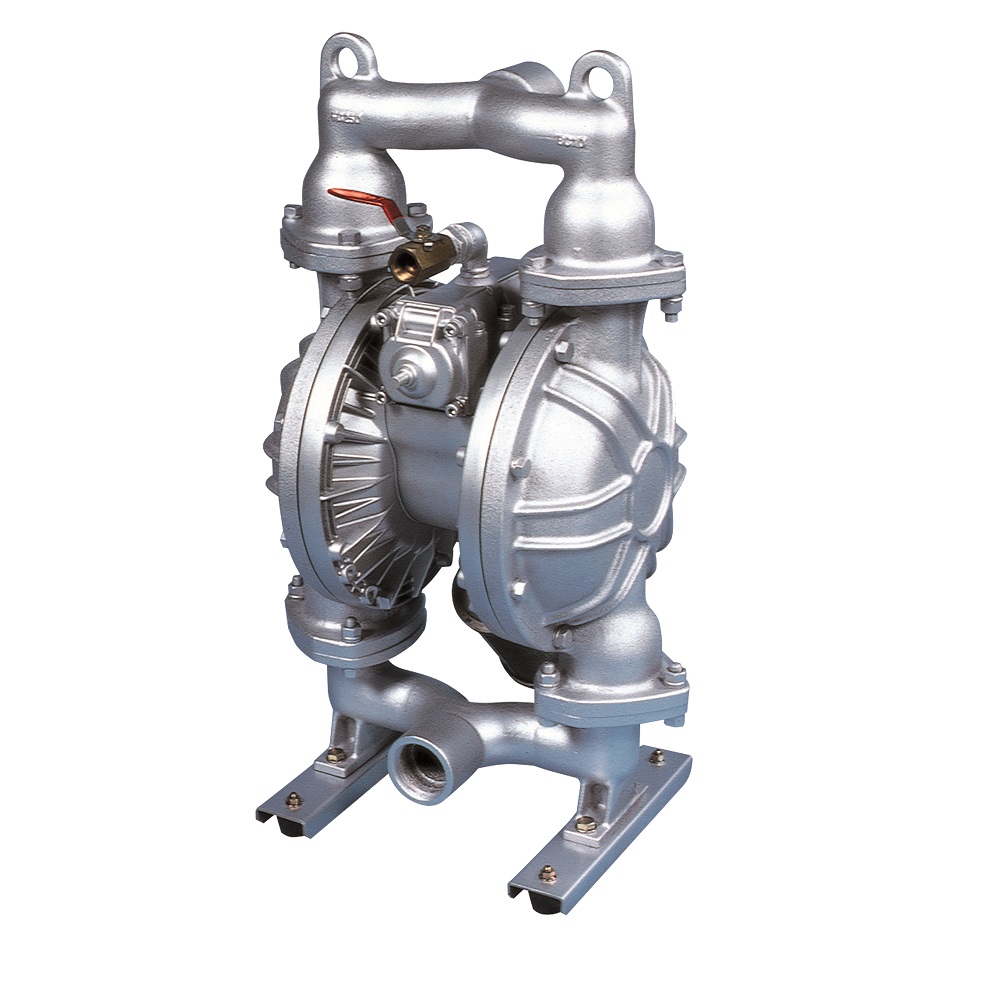

- Lubrication Systems: Protects machinery

- Boiler Systems: Safe steam generation

- Textile Machinery: Maintains consistency

- Printing Machines: Ensures smooth output