Float Switch Combined with Analogue Temperature Output

- Use of combined devices in almost all kind of fluids

- Detection of levels and temperature in shipbuilding, off-shore, petrochemical and chemical sector, plant construction, mechanical engineering, hydraulic power packs, cooling systems, potable water treatment, food and beverage industry, power plants and other power systems.

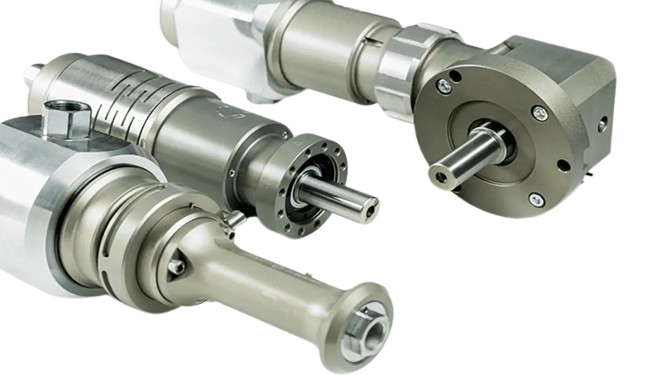

A float switch with analogue temperature measurement is a device commonly used in tanks or containers to monitor liquid levels while simultaneously measuring the temperature of the medium. It combines two functions in one: level detection via a float switch and analogue temperature measurement. The device typically includes a microcontroller that converts the resistance signal into a standard analogue output signal, such as 0–10V or 4–20mA.

Operating Principle:

The operating principle of a float switch based on a Reed contact involves using the Reed element as a switching mechanism. A float switch consists of a buoyant body (float) that moves with the liquid level. This float contains a magnet. As the liquid level rises or falls, the magnet approaches a Reed contact, which is housed in a glass bulb and contains two ferromagnetic contact leaves separated by a small air gap. When the magnet gets close enough, the magnetic field causes the leaves to close, completing an electrical circuit. This closed circuit can then trigger a signal—such as an alarm or motor control.

Analog temperature measurement is performed using accurate sensors like the PT100 or PT1000, which operate based on the change in electrical resistance of a metal with temperature. A PT100 sensor contains a platinum resistor whose resistance increases with temperature. A PT1000 sensor functions similarly, but its base resistance is 1000 ohms instead of 100. These sensors provide highly accurate resistance values that correlate directly with the temperature of the medium. The resistance is then converted into temperature readings using a measuring device or evaluation circuit. These readings can also be integrated into control and regulation systems for automated temperature monitoring and adjustment.

Advantages:

- Reliable Level Detection: Robust and proven technology for accurately monitoring liquid levels in tanks or containers, suitable for various fluids and conditions.

- Accurate Temperature Measurement: Provides precise analog readings for effective process control and early issue detection.

- Combined Functionality: Monitors both level and temperature in one device—saving space, cost, and installation effort.

- Easy Installation & Maintenance: Simple setup with minimal upkeep; no internal moving parts in the liquid.

- Robust Design: Built from durable materials for reliable use in harsh industrial environments.

- Quick Response: Fast reaction to level and temperature changes for timely alerts or control.

- Adaptability: Available in various sizes and designs to suit different applications.

- Enhanced Safety: Continuous monitoring helps prevent overfilling, overheating, and other hazards.

Applications & Industries:

- Industrial Automation: Monitors cooling and lubrication fluids in machinery to ensure smooth operation and optimal conditions.

- Mechanical Engineering: Used in hydraulic and lubrication systems to track oil levels and temperature—boosting machine life and minimizing downtime.

- Chemical & Pharmaceutical: Ensures safe handling and controlled processing by monitoring chemical levels and temperatures in tanks and reactors.

- Power Generation: Tracks fuel and coolant levels in power plants for efficient and safe operation.

- Food & Beverage: Maintains quality and safety by monitoring levels and temperatures of ingredients and cleaning solutions.

- Water & Wastewater Treatment: Ensures efficient system performance by monitoring fluid levels and temperature in treatment tanks.