Magnetostrictive Level & Temp Sensor (4–20 mA)

In today's highly technological world, level and temperature measurement in industrial plants, tanks, and containers is becoming increasingly crucial. These measurements are essential to industrial processes and have a significant impact on efficiency and safety. Reliable analogue magnetostrictive level measurement, combined with a temperature sensor such as a PT100 or PT1000, has proven to be highly effective. It enables continuous, precise monitoring of liquid levels and provides accurate temperature measurement.

Operating Principle:

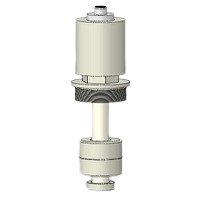

The magnetostrictive measurement principle relies on the unique properties of certain materials that respond to magnetic fields. In this system, a magnetostrictive wire —made from a special alloy— reacts when exposed to a magnetic field.

In level measurement applications, a float containing a magnet moves up or down with the liquid level. A tube housing the wire runs vertically through the float. When an electrical pulse is sent through the wire, it generates a magnetic field that travels along the tube. When this field reaches the magnet in the float, it causes a small, localized distortion (mechanical wave) in the wire.

This wave travels back through the wire and is detected by a sensor at the starting point. By precisely measuring the time delay between the electrical pulse and the return of the wave, the system calculates the float's position—and thus the liquid level—based on the known wave speed.

The result is a highly accurate, non-contact level measurement that can be displayed, transmitted, or used for process control — such as level indication or automated filling.

Analogue temperature measurement is performed using highly accurate temperature sensors such as the PT100 or PT1000. These sensors operate on the principle that a metal's electrical resistance changes with temperature. A PT100 sensor contains a platinum resistor whose resistance increases as temperature rises. A PT1000 sensor works the same way, but with a resistance value 1,000 times higher than that of a PT100.

These precision sensors provide reliable analogue signals directly related to the temperature of the liquid or medium. The resistance values are then converted into temperature readings and shown on a suitable display or evaluation unit. The measured values can also be transmitted to control systems for process monitoring or to automatically regulate temperature in the facility.

Advantages:

- Precise Measurements: Real-time monitoring of level and temperature ensures accurate data for optimized processes.

- Efficient Control: Continuous measurement enables better process management and resource savings.

- Early Fault Detection: Detects issues early to prevent downtime and equipment damage.

- Improved Safety: Monitors critical conditions like overfilling, leaks, or overheating.

- Easy Integration: Digital interfaces allow smooth integration into control systems.

- Versatile Use: Suitable for a wide range of industries and environments.

- Cost Savings: Prevents failures and reduces repair and maintenance expenses.

- Eco-Friendly: Optimizes energy and material use, reducing environmental impact.

Applications & Industries:

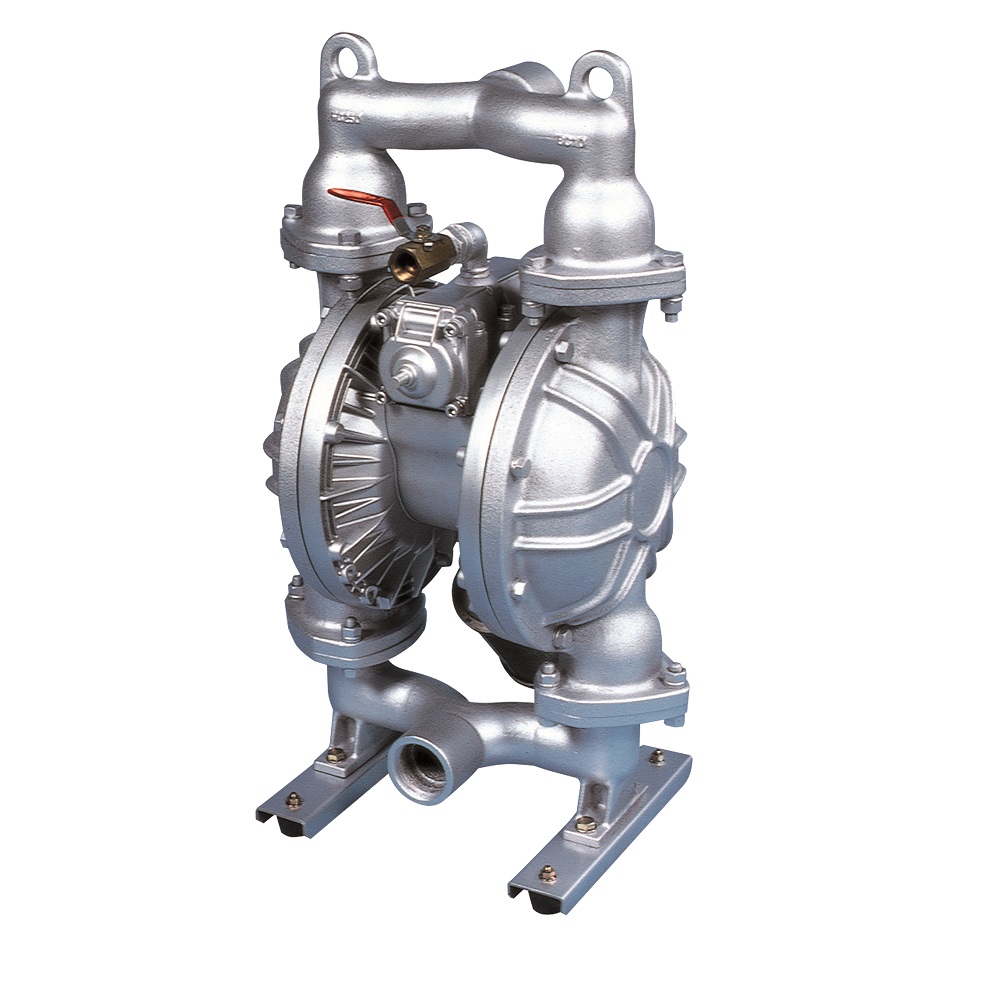

- Hydraulic Systems: Monitor oil levels and temperature to ensure efficient operation and prevent overheating or leaks.

- Cooling Systems: Control coolant level and temperature to protect equipment from heat damage.

- Lubrication Systems: Ensure proper lubrication and prevent wear by monitoring lubricant levels and temperature.

- Pressure Vessels & Tanks: Accurately measure liquid levels and temperature for safe operation and compliance.

- Steam & Boiler Systems: Optimize steam production and safety by tracking water levels and temperature.

- Textile Machinery: Control dye and chemical levels for precise and consistent fabric processing.

- Food Processing: Ensure quality and safety by monitoring liquid levels and temperature in production systems.

- Environmental Systems: Support wastewater treatment and regulation compliance through accurate monitoring.