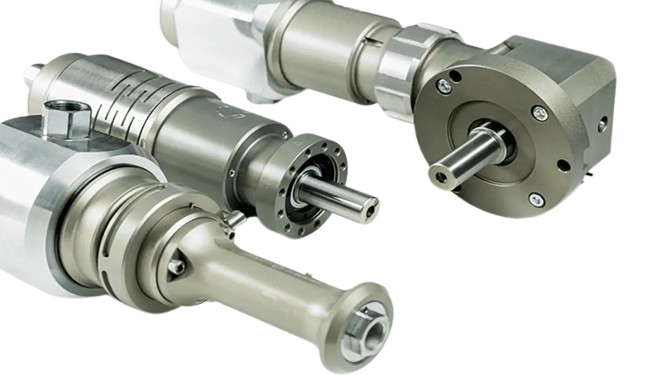

2/2-Way Solenoid Valve, Pilot Operated

Due to the high electromagnetic force required, direct-acting solenoid valves are not suitable for switching large nominal diameters and/or large pressure differentials. To reduce the required electromagnetic force and allow for the use of smaller, more energy-efficient solenoid coils, pilot-operated solenoid valves are used.

In these valves, the main sealing element in the form of a diaphragm or piston closes the main seat of the valve. The medium fills the space above it through a small hole in the diaphragm or laterally around the piston. The pressure on the diaphragm or piston causes them to close the valve seat. A smaller, directly operated solenoid valve in NC or NO design, the so-called pilot valve, can relieve the space above the diaphragm or piston, causing them to lift off the main seat and allow flow through the valve. With this principle, a corresponding minimum pressure of the medium is necessary to lift the diaphragm or piston off the valve seat. The function of the pilot valve (NO or NC) determines whether the entire valve is normally closed or normally open. The advantage of pilot-operated valves is the ability to switch high pressures at large nominal diameters using relatively small and low-power solenoid coils.

Brass Products:

Type 50A - normally closed, brass body, pilot operated, DN 10 mm, G3/8 (- G1/2)

Type 51 - normally closed or open, brass body, pilot operated, DN 15 – 50 mm, G1/2 – G2

Steel Products:

Type 60 - normally closed, body made of stainless steel 1.4301 (AISI 304), pilot operated, DN 10 mm, G3/8”

Type 62 - normally closed or open, body stainless steel (AISI 304), pilot operated, DN 13 – 50 mm, G1/2 – G2

Type 63 - normally closed or open, body made of stainless steel 1.4301 (AISI 304), piston shut-off, pilot operated, DN 15 – 50 mm, G1/2 – G2, pmax up to 100 bar